Traditionally chainsaws are known to be used for wood projects such as tree removal. But when your project calls for cutting deep into concrete, a chain saw specified for concrete should be your first choice. These types of saws can be used on all different types of concrete, bricks, masonry, and steel objects as well. Concrete chainsaw blades are made of mainly diamond grit which has incredible durability for these different types of surfaces. Because of the common use of these chainsaws in home construction, government projects, and non-residential buildings, they are becoming an essential tool for all construction companies.

Purpose of Concrete Chainsaws:

For most construction jobs, a concrete chainsaw is one of workers’ most used tools because of how diverse a tool it can be. Demolition jobs, mining works, and even firefighters occasionally use these intensified concrete chain saws for their jobs. These chainsaws are perfect for tight, hard-to-reach areas where big equipment can’t reach. Concrete chainsaws can easily make small, deep openings in these tough surfaces to further enhance any project that you are working on.

These chainsaws are welded with diamond segments to increase the hardness and endurance of the cut you are performing. Because these concrete chainsaws have pressurized water circulation instead of bar and chain oil in regular chainsaws, heat reduction is the main component.

A concrete chainsaw is a perfect tool for these hard, tough surfaces because of the little amount of kickback they produce. These saws hardly ever get caught because concrete is a fibrous, brittle structure.

Different Types of Concrete Chainsaws:

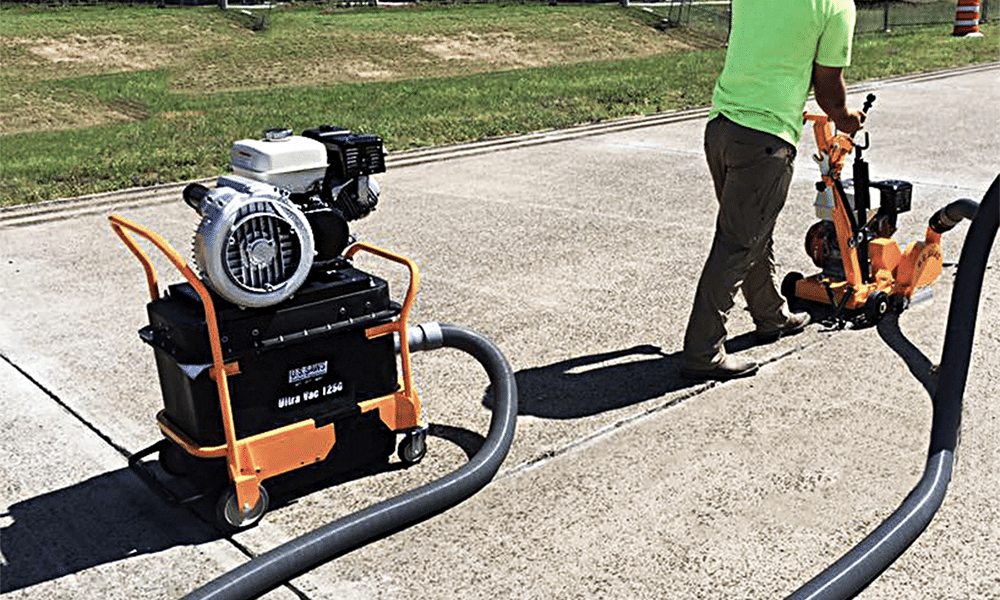

Depending on the variety of jobs you are working on will depend on the type of concrete chainsaw that you use. Gas and air-powered chainsaws are very different, so it is important to gain some knowledge beforehand when deciding on your next chainsaw. At U.S. Saws, we offer different chainsaws to make your next project become easier and more efficient to get the job done as quickly as possible:

Ductile Iron Cutting Air Chainsaw: These chainsaws are designed for the demanding jobs you come across when working in the construction business. They are the perfect saw for cutting ductile iron and other types of pipe that you may find. This type of chainsaw has different capabilities that are able to cut from 15” up to 20” deep of piping. The Ductile Iron Air Chainsaw makes sure safety is a priority and ensures the job gets done as quickly, but efficiently as well.

Concrete Cutting Air Chainsaw: This air-powered chainsaw is designed to cut through concrete walls, underground vaults, concrete pipes, and other tough structures. The cutting air chainsaw is used by contractors who require high performance and are very low maintenance, emissions-free tools. Because it is air powered, you can use this chainsaw for unground projects and not worry about the dangers of breathing in fumes that most gas-powered equipment produces. With a long service life, this saw will save you on maintenance costs in the future and become an everyday tool for your projects.

Ductile Iron Cutting Gas Chainsaw: With new 695XL features, this chainsaw has an easy-to-start engine with a high ignition system ready to tackle any surface in its way. These chainsaws are durable and have long-lasting components such as the muffler, carburetor, and piston to provide you with sustainability for years. This is the highest horsepower ICS gas chainsaw that is mostly used by construction, contractors, and concrete professionals. Packages with this chainsaw include a guide bar, PowerGrit Ductile Iron Chain, 10” Pipe Clamp, and Storage Bag Package to ensure you are getting your money’s worth.

Concrete Cutting | ICS 695XL-16 F4 Heavy: The most versatile gas-powered chainsaw from U.S. Saws. Available with 12 In. (30 cm) – 16 In. (40 cm) guide bars and the entire line of max, ProFORCE, and powerhead series Diamond Chains make this chainsaw perfect for any hard-cutting jobs you are working on. This chainsaw also involves the package of a guide bar, PowerGrit Ductile Iron Chain, 10” Pipe Clamp, and Storage Bag. Out of all the chainsaws with U.S. Saws, this is the lightest weighted one to use as well.

With different types of chainsaws available, U.S. Saws is here to help you find the perfect match for your next project. From tough concrete cutting to intensified pipe cutting, we have the chainsaws ready for your specific job to get done quickly and efficiently.

How to use a Concrete Chainsaw

Safety First:

Using a chainsaw is a dangerous aspect of the construction business. Because of this, safety should always be the first step when using a concrete chainsaw. Make sure you are well equipped with the proper clothing, hard hat, eye protection, and gloves. Once this is executed, checking the area before the cut is the next step.

Check the area and be sure that no electrical wires, plumbing, air ducts, or other dangerous obstructions are in the way of the cut you are about to make. The chain on the saw should be inspected to ensure the tension is correct and not too high as well. This is important to ensure the chain will work the way you need it to when performing your cut.

Plan Your Cut:

Planning your cut before the initial cut is an essential part of using these chainsaws. You can use a marker to help with a visual guide during this process. One thing that is important to remember is to always cut the bottom of the area first, cut the top of the area afterward, then finish with the sides.

The recommended technique that is the easiest and safest is called “plunge cutting”. Having a straight cut is a top priority and this process ensures this happens.

The Execution:

When it is finally time to cut your surface, start by slowly putting the nose of the guide bar straight into the surface. It is important that the trigger is continuously held on full throttle throughout the whole cut. The nose of the bar should be lined up with the visual guide you created while you slowly plunge.

During this process, a good amount of force should be applied. But if you push too much force, the saw will stall and the chain will untimely not have enough speed to continue with the cut. Having not enough force will cause the diamonds of the chain to glaze over the concrete. It is essential to find the right amount of force and maintain a constant RPM throughout the cut when using these chainsaws.

If you ever need a faster cutting speed, opening up the diamonds on the chain can execute this. This is done if you are struggling to make a cut on the surface you are working on.

Rent vs Buy:

Depending on the work you do will help you choose whether you should invest in buying a chainsaw or renting one. Whatever side you pick, you need to decide what will help your projects in the future the most, as well as financially for your business to make sure you get your money’s worth.

Rent:

If you don’t normally use concrete chainsaws for your everyday projects, your best decision is to rent. There isn’t much need to buy a chainsaw for one-time use. Because there are several different types of chainsaws, if you do decide to rent, you need to ensure you get the right one for the specific project that you will be working on.

There is a big difference between gas and air chainsaws that have different amounts of power produced. Inspect the project you will be working on first before you start any of the renting processes for this equipment.

Always make sure the chainsaw you are renting is up-to-date and performs the way it is supposed to. The last thing you want is to start on your project with a faulty chainsaw that will waste valuable time and money.

Buy:

If your business is heavily involved with concrete projects, investing in a high-quality concrete chainsaw will be well worth the money. Having your own chainsaw means you never have to worry about finding a chainsaw to rent in urgent times. Struggling to find a chainsaw to rent can make or break an important project that is urgent.

When you decide you want to buy, going the cheaper route isn’t always the best. Yes, these chainsaws are expensive. These types of chainsaws turn into a financial commitment that will be worth it in the end.

Concrete chainsaws that you buy from U.S. Saws are high-quality and satisfaction guaranteed. With the most durable and sustainable chainsaws available, you will lower your maintenance costs and be able to finish every project that is thrown your way when it comes to concrete and other tough surfaces needed to be cut.

Frequently Asked Questions:

How Long Do Concrete Chainsaws Last?

The average life expectancy of one of these chainsaws is at least 10 years. How long your chainsaw lasts all depends on how well you take care of it. Maintaining and cleaning your chainsaw will provide you with longer usage times for them. Be sure to replace any parts as soon as possible and lubricate the chainsaw before and after every use as well. If you maintain it and clean it thoroughly after every use, you can have your concrete chainsaw for a very long time, and will be worth the money you spent originally.

This also depends on the brand you choose to buy as well. Chainsaws are a huge market so there are numerous amounts of different brands and manufacturers. Each brand uses different materials and has different needs so your life expectancy on these chainsaws will always differ.

How Deep Do You Cut Concrete?

Most uses for a concrete chainsaw are for small openings or different tough surfaces. Because of this, different chainsaws can cut concrete up to 25 inches thick. Some hydraulic concrete chainsaws will cut more than 25 inches. Most gas-powered chainsaws will cut 12 to 16 in. deep depending on the model, bar, and chain being used. Depending on what chainsaw you are using and the material you are trying to cut will all affect how deep you can cut. You need to make sure you have total control of your chainsaw to ensure you don’t cut deeper than needed for your surface.

When is it Time to Replace Your Chainsaw?

When your chainsaw starts making you work harder than you usually do, this is when it is time to think about finding a replacement. Your chainsaw might become sluggish and the cuts you normally make will take longer. Missing teeth, rust, and smoking from the chain are also noticeable factors that it is time to find a replacement. Most of the time it is only the chain that needs to be replaced when these difficulties start occurring. Always inspect your chainsaw before each project so you can notice any issues beforehand.

Can you Cut Concrete Dry?

Cutting concrete with any saws should never be done dry. This type of cutting should be strictly done with a wet system. This helps reduce dust that can become health hazards within the respiratory system. Wet cutting helps with more precise cuts and puts less pressure on those using the chainsaw as well. Even though this is by far a messier method, this is an important cooling aspect for your diamond blades to ensure they are being used properly for your cutting project.

Is “Kickback” a Safety Issue When Using These Chainsaws?

According to a research study recently published in the International Journal of Occupational Safety and Ergonomics, abrasive chainsaws generate nearly 50% less kickback energy than circular cutoff saws – making them a safer choice when cutting these tough surfaces. Diamond chains that are on your concrete chainsaw grind through concrete with small diamond teeth that are without hooks. If you use the preferred method of plunging straight into the surface when starting your cut, there will be no kickback. Wood-cutting chainsaws give kickback because the sharp hooked teeth grab the wood.

Where to Buy Your Next Concrete Chainsaw?

Concrete chainsaws are becoming a popular tool for the construction business. Because of their efficiency and safety features, choosing to have this piece of equipment is crucial for your next project. There are many different factors that go into deciding on your next concrete chainsaw. This can be a difficult process to ensure you get your money’s worth, but U.S. Saws has you covered throughout the whole process. With different types of chainsaws and attachments available, U.S. Saws will get you the most high-quality chainsaw to fit your project’s specific needs.

U.S.SAWS principals each have over 30 years of experience in the concrete repair industry and are very knowledgeable about Sawtec products. We are dedicated to improving contractors’ brand loyalty through innovative product enhancement and personal customer service. We bring to market innovative construction products which provide our customers value by improving job site productivity and safety as well.

U.S. Saws is an innovator in the tool industry. Concrete chainsaws are an essential tool for all tough surface cutting needs that will take your project to the next level. As there are many factors to consider in choosing the proper concrete chainsaw for your project, engaging with a company to help guide you to the right knowledge and concrete chainsaw equipment will ensure your project is completed promptly and in the right manner. Contact U.S. Saws today to find the concrete chainsaw to meet your specific project needs.