The job of a municipal water and sewer worker is not easy. Accessing those water and sewer systems takes a lot of grit and elbow grease. While these jobs are not the most glamorous or cushy, they do provide a significant service to the community without which access to clean water would be limited. Getting dirty may be part of the job, but there are ways to reduce the dirt and the labor in order to make the job a little easier on the worker. The following are five key tools to help make a municipal water and sewer workers life a little less complicated.

Manhole Cover Lifter

Manhole covers are a necessary part of our water and sewage systems. These covers are designed to protect our water systems from access by unqualified individuals. Manhole covers are incredibly heavy for that specific reason. The weight of some manhole covers can exceed 900 pounds. Without the proper tools, most manhole covers are not easily lifted by the average human being. Companies like US SAWS have manufactured manhole cover lifters to reduce the effort needed by municipal workers to lift manhole covers and access water systems in order to make necessary repairs and conduct required maintenance. Because of the varying sizes and weights of manhole covers across the country, US SAWS has developed different lifters for different sized manhole covers. For covers weighing 300 pounds or less, the Supreme Duty Collapsible Dolly Magnetic Lifter is the perfect tool. Equipped with rubber wheels and a supreme duty magnet, this lifter is ideal for covers up to 36 inches in diameter, and it breaks down easily for quick storage. Manhole covers weighing up to 600 pounds may be easily moved using the Aluminum Heavy Duty Collapsible Dolly. This cover lifter is also ideal for covers up to 36 inches in diameter, comes equipped with eight inch hard wheels, it also relies on a supreme duty magnet. This system is perfect for uneven textured surfaces and provides dual position lifting points. Heavy manhole covers weighing about 900 pounds require an even stronger lifter. The Curved Heavy Duty Magnetic Lifter makes fast work of those heavy manhole covers while protecting workers from back injury. This lifter is equipped with eight inch hard wheels and lifts using a mega duty magnet. It also folds down for easy transportation and storage.

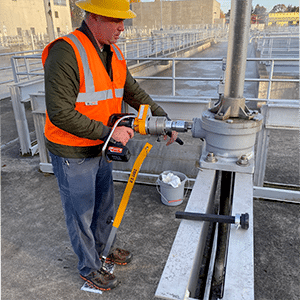

Valve Exerciser

One task of waste and water workers is securing the quality and quantity of water accessed by the community. In order to ensure the access and flow of water remain consistent and steady, regular maintenance is required for all the systems. Perhaps the most crucial component of our water and waste systems are the valves located throughout the systems. Valves are critical to regulating, directing, and controlling water. It is important that is valves do not become stiff and rigid I must be exorcised in order to maintain flexibility in order to prevent issues with backflow. Many of these valves are not in easily accessible locations. U.S. Saws has developed battery powered valve exercisers to make the job easier on municipal water workers. One such valve exerciser is the VEX-400. This powerful and portable valve exerciser uses 18 Volt batteries and a Metabo drill motor to get the job done, providing workers the benefit of a heavy duty powerful tool that can be used in tight and awkward locations Pump.

Utility Pump

One great foe of every water worker is the problem of standing water. Standing water Makes it difficult for workers to access many underground structures including meter pits and valve boxes. It is essential that the water is removed so that the workers have a way to access their work site. One easy way to do this it’s through the use of a utility pump. U.S. SAWS is a proud supplier of the Dewalt Battery Powered BP1520 Battery Pump. This powerful pump has a PVC body and housing protecting it from rust, corrosion, dents, and bends. It is powered with either a 20 Volt DeWalt or 18 Volt Milwaukee battery and with its slim design works well in tight spaces that are off in the bane of a municipal workers’ day. This powerful tool can pump 15 gallons a minute and weighs only 6 pounds making it the perfect tool for backbreaking work.

Hand-Held Saws

What water workers toolbox is complete without a saw? At some point water workers will be required to cut pipes in confined underground spaces. Most saws are powered electrically or using gas; however, tight and confined spaces make using electrical or gas powered saws less than perfect options. U.S. Saws has developed air powered handheld saws. this technology not only makes the job easier for the worker, but protects him or her from harmful fumes emitted buy gas powered saws. One such saw is the HS-125 Hand-Held Air Powered Saw. This air powered saw has no combustible parts, requires low maintenance, and has a lightweight design. It has a maximum cutting depth of five inches and is ideal for confined space cutting. An added bonus of this super saw is that it allows for wet or dry cutting, making it a highly versatile saw for any workers toolbox.

Belly Saws

The 5th tool required to make water and sewer workers lives simpler is the belly saw. The belly saw is the perfect tool for cutting pipes in what conditions and its design makes it safer to operate than most other saws. From the guard design that covers the blade to the straps that attach directly to the pipe in order to prevent kickback, the belly saw is a utility worker’s best friend. of course there are different belly saws that are dependent on the size of the pipes that need to be cut. One such saw is the US SAWS Air Powered Belly Saw. This offering from U.S. SAWS varies depending on the sides of the pipe and comes and offerings that range from 8 to 24 inch pipes, 24 to 48 inch pipes, and 48 to 72 inch pipes. The fact that these saws are air powered only increases the benefit to the workers, relieving them from harmful fumes and allowing them access to powerful tools in wet conditions. This saw make easy work of PVC, ductile iron, cast iron, and other heavy duty materials through the use of its Tiger Tooth blade. With its safe and accurate cuts the air powered belly saw is a must have for every municipal worker.

U.S. SAWS is a leader in the underground tool industry. Contact us today to discuss updating your tool box!